When it comes to purchasing a new pressure vessel, one of the greatest concerns is typically cost. For many companies, the initial cost becomes the overriding issue.

However, elements in the fabrication, design, and process phase should be considered when selecting a pressure vessel aside from just price. In a real sense, “quality justifies the cost.” While, cost still plays an important factor, it should not be the primary deciding factor when purchasing a pressure vessel. Material selection, quality welds, and overall design of the pressure vessel should also be a part of the decision making process.

Material Selection

Perhaps the single most important factor in the fabrication of any pressure vessel is the material selection process. The use of the correct possible material for your pressure vessel can not be understated. The individual costs of materials are subject to market pressures and demands, so the price can fluctuate. Using the wrong material for a pressure vessel can have serious consequences. Therefore, it’s important to focus on the quality and suitability of the material for your pressure vessel.

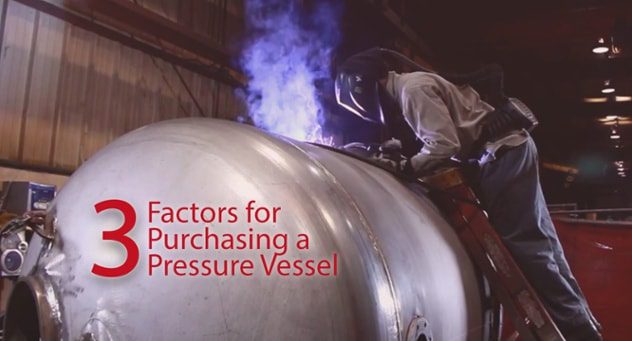

Quality Welds

Locations where metal is joined together by welds can be a primary failure point for a variety of reasons. The most common reason for weld failure is improper welding. It takes expertise and time to properly perform quality welds that enhance the strength of the vessel and conform to acceptable standards.Since improper welds can lead to catastrophic results during operation, the additional cost should be justified to ensure your pressure vessel has quality welds.

Design: Process And Engineering

Design is where all the elements of user requirements, operations, and more come together to produce the plans for the fabrication of your new vessel. There isn’t a magic price when it comes to the design and engineering of a pressure vessel. It’s important to remember the phrase that you often get what you pay for and low quality design and vessel fabrication will affect your end product. Ultimately, selecting a fabricator with quality design and engineering tactics should be a priority when purchasing a pressure vessel.

Pressure vessels can present unique challenges and these challenges are often be left out of the consideration of cost. All the above factors have to come together to create the final product that will engage in a successful operation that is free from defect. While there is little doubt that costs are a factor in procuring a vessel, that is not the most significant factor to consider. Quality in materials, welds and design all have to come together seamlessly to produce an effective, efficient and well-made product to make sure that you get the most for your business dollar.

ASME Informational

ASME Informational Tank Materials

Tank Materials